Iron ore is a natural raw material exploited worldwide, this material is processed for use in the steel manufacturing industry.

Initially, iron ore was crushed and then screened to separate into lumps and fine iron ore. If iron (Fe) content in treated ore is> 60%, it is transported directly to the factory to produce iron and steel.

In commercial trade, there are many types of iron ore with different particle sizes and Fe content:

Iron ore inspection scopes of IMI Vietnam are as follows:

1. Pre-shipment inspection at warehouse/open yard (PSI inspection)

- Stockpile quantity survey

- TML inspection with fine iron ores which may liquefy

- Sampling, sample preparation and analysis

- Condition inspection

- Other scope of inspection required

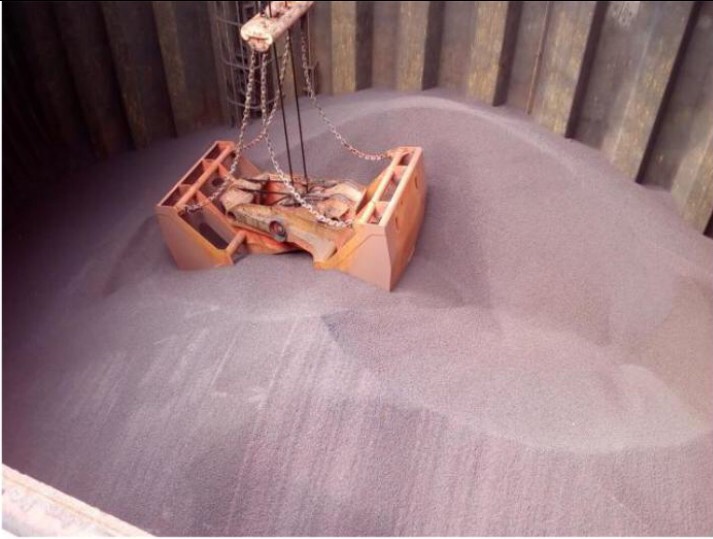

2. Loading/Discharging inspection

- Quantity inspection by Draft survey

- Quantity inspection by truck scale

- Cargo hold cleanliness inspection

- Loading/discharging supervision

- Sampling and sample preparation

- Analysis chemical and physical, sizing analysis

- Other scope of inspection required

3. Analysis parameters as below:

|

Chemical composition |

Physical composition |

||

| No.: | Item | No.: | Item |

| 1 | Fe | 1 | Tumble Index (% +6.3mm) |

| 2 | Moisture | 2 | Abrasion Index (%-0.5mm) |

| 3 | SiO2 | 3 | Cold compression strength (daN/p) |

| 4 | Al2O3 | 4 | Porosity |

| 5 | CaO | 5 | Reducibility – Linder at 860 deg C |

| 6 | Go | 6 | Bulk density |

| 7 | T.Fe | … | … |

| 8 | MgO | ||

| 9 | MnO | ||

| 10 | TiO2 | ||

| 11 | K2O | ||

| 12 | Na2O | ||

| 13 | V2O5 | ||

| 14 | Phosphorous | ||

| 15 | Sulfur | ||

| 16 | LOI | ||

| 17 | Cu | ||

| 18 | Zn | ||

| 19 | Pb | ||

| … | … | ||

For further advice on iron ore inspection service of IMI Vietnam, please contact:

IMI Vietnam Co., Ltd

Address: 2/101 Phuong Khe Street, Dong Hoa Ward, Kien An District, Haiphong City, Vietnam

Email: info@imi.vn

Hotline: +84 372 190781

Website: www.imi.vn